This is a bi-weekly newsletter about climate solutions. To receive the Gigaton in your inbox each week, subscribe here:

Gigaton Potential

Experts at Nature Sustainability estimate that Mass Timber (MT) construction could store 700 million metric tons of carbon1 per year for the next thirty years if we transitioned 90% of new construction to timber systems. That’s 21GtC by 2050 if we build with wood instead of concrete and steel.

For reference: in 2019, the world emitted 51 gigatons of CO2-equivalent greenhouse gasses. Project Drawdown estimates we need to cumulatively eliminate 1,000 GT from 2020-2050 to keep global warming below 2 degrees Celsius.

You Might be Interested If…

You see enormous potential for renewable (and reusable) materials to transform how we think about building design and how we build.

You want to tackle the embodied carbon of a building’s life cycle, not just the operating carbon (because more and more research points to how large an impact the embodied carbon challenge is).

You see a future where the built environment’s supply chain is industrialized to improve efficiency and reduce waste.

What You Should Know

Mass timber is a family of engineered wood products that can prescriptively replace steel and concrete construction. Current codes provide for up to 18 stories, with room to go higher.

🌲 “But there isn’t enough wood!”

We have enough wood in America to sustainably harvest wood for even the most optimistic projection of mass timber growth. To be clear, this wood comes from trees 18” in diameter or less, not from old growth trees or national parks.

🧯 “But isn’t wood susceptible to fires?”

Depending on the thickness, mass timber has an inherent fire resistance rating in excess of 3 hours, which far exceeds the typical 2-hr code requirements and easily achieves the 3-hr code maximum for any construction material.

With those misconceptions out of the way, it’s important to recognize that MT is the only structural building material that both reduces carbon emissions and stores CO2 long term. Every timber species stores carbon differently, but for example, one cubic foot of Douglas Fir-Larch stores 55 lbs of CO2.

Office Example

A six-story office building in Portland, OR used nearly 83,000 cubic feet of MT, equating to ~2,100 metric tons of CO2 stored. The project also avoided 800 tons of CO2 pollution by replacing concrete columns and floor plates with MT. Together, that’s a 2,900 metric-ton reduction of CO2.

Zooming Out

Green concrete and steel are still in their infancy, but mass timber is in use today. According to The Economist, MT will account for $1.4B of the $14T global construction industry by 2025 and is expected to grow by over 13% per annum into the mid-2020’s. Demand for the product outstrips supply of knowledgeable providers, so the primary bottleneck is in the maturity of the construction value chain.

Key Players

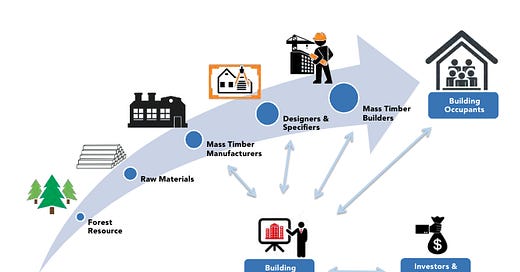

Mass Timber Value Chain

Source:

https://www.masstimberreport.com/

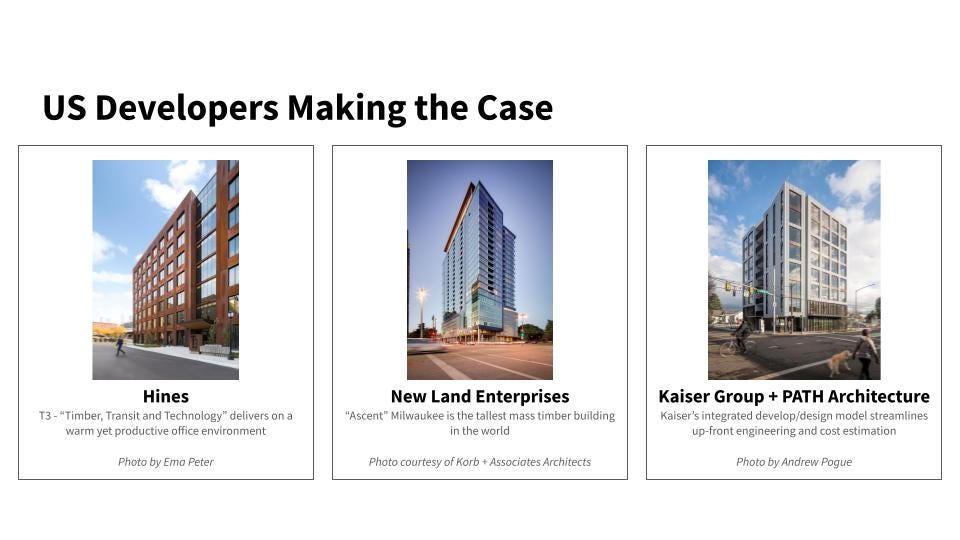

Real estate is valued based on future cash flows, so the business case for mass timber starts with a future tenant. Tech giants like Google, Microsoft and even Walmart have justified a higher price (MT can be 5% to 10% more expensive) by making the case that the biophilic properties of wood will increase worker productivity while reducing the company’s carbon footprint. Beyond these large clients with deep pockets, few developers have managed to make the case that a timber building commands higher up-front costs. There are some who are charting the way, including Hines, New Land Enterprises, Kaiser Group, Killian Pacific, Adre, Trent Development, oWOW, and Malick Development.

Beyond developers and clients, there are many stakeholders that contribute to the mass timber value chain:

We are also seeing an entrance of integrated design-delivery providers that believe in the industrialization potential of mass timber:

Opportunities for Innovation

🌿 Prefabrication & Modular Construction

“Prefab” = factory-made components that are shipped and assembled on site.

“Modular construction” = off-site prefabricated building components that are modular in nature - they can be stacked or grouped to build a semi-customizable structure.

The challenge here is balancing the geographic needs and regulations of the site while standardizing major components. Every building is unique, but efficient factories require standardization.

See Juno, FactoryOS, SLI and a thoughtful take on why Katerra failed.

🌿 Supply Chain Optimization

Most North American MT products are trucked at low miles-per-gallon efficiencies. Compare that to Europe, where an optimized supply chain of rail and cargo ships significantly improves transportation efficiency.

The MT supply chain first ships wood fiber from sawmills to manufacturers, then to secondary processing facilities, then to job sites. How do we optimize the secondary processing step to reduce shipping of unnecessary waste?

🌿 Robotics & AI

Digital twins, Building Information Models, and Virtual Reality all have a space in the construction process. How do we bring those components upstream into the manufacturing and fabrication process to create quality, precision products that are engineered to be built quickly and with minimal waste?

See McKinsey’s take on con-tech opportunities.

🌿 Sustainable Forestry

With a new demand stream for wood products we will see increased scrutiny on the forestry practices throughout North America. How do we balance output with sustainable harvesting? FSC-Certified wood is the gold standard in today’s harvesting practices, but is a 3rd party, for-profit certification the best way to accomplish our sustainable harvesting goals?

Author Bio: Rae Oakley is a second-year Stanford MBA who is passionate about building better buildings. Her work has spanned sourcing sustainable construction materials to creating new financial products for homebuyers. She is always ready to talk about innovative wood products, unexpected real estate trends, or how she designed her ideal mechanical keyboard.

With insights from Mass Timber Experts: Ethan Martin, Director of Sustainability and Mass Timber at DCI Engineers, and Steve Marshall, Founder and President at Mass Timber Strategy.

Wood fibers store carbon instead of CO2. Every wood stores carbon differently, but as an example, one cubic foot of Douglas Fir-Larch stores 55 lbs of CO2. If 700 million metric tons of carbon were stored entirely in Douglas Fir-Larch, that would equate to 2.6 billion metric tons of CO2 per year.